WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Waste tire pyrolysis plant has two types, one is batch type waste tire pyrolysis plant, the other one is fully automatic waste tire pyrolysis plant. The function of batch type waste tire pyrolysis plant and fully automatic waste tire pyrolysis plant is same, but the fully automatic waste tire pyrolysis plant has some extra benefits compared with the batch one.

Compared the fully automatic waste tire pyrolysis plant and the batch plant

Compared the fully automatic waste tire pyrolysis plant and the batch plant

1.More efficient to process the waste tires

The fully automatic waste tire pyrolysis plant has continuous feeding and slagging system, thus no need to stop the machine and wait it to be cooled down for discharge system. If there is no emergency happens, it can run continuously for one month or even longer. But the batch type waste tire pyrolysis plant may need six or seven hours to stop during each batch( the time basically spend on feeding, heating and slagging). In a word, if they both can dispose 10t waste tires per day, the fully automatic waste tire can dispose 300t waste tire a month, but the batch one only can dispose 230t.

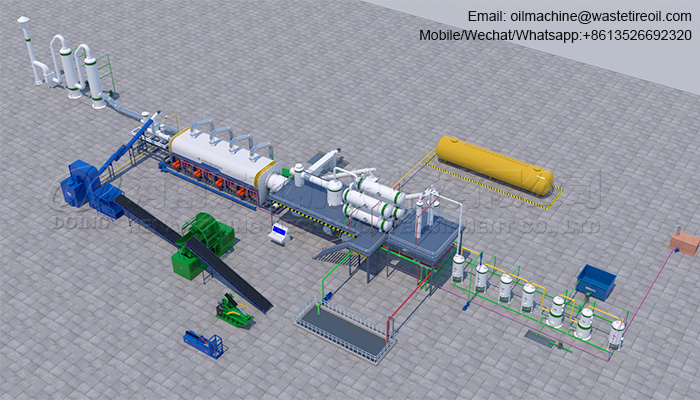

Panorama of the fully automatic waste tire pyrolysis plant

Panorama of the fully automatic waste tire pyrolysis plant

2.Less labors and energy using

For the fully automatic waste tire pyrolysis plant, it only needs to be fueled one time to start working. But for the batch one, every batch, it needs time and fuels to heat the pyrolysis reactor. And owing to it is fully automatic with PLC control system, it only needs 2-3 workers to take care of the plant. Then the batch waste tire pyrolysis plant need more workers to feed and discharge.

The continuous heating process of fully automatic waste tire pyrolysis plant

The continuous heating process of fully automatic waste tire pyrolysis plant

3.Better for environment.

The whole process of fully automatic waste tire pyrolysis plant from raw material feeding to slagging is operated in a completely sealed environment, and the excess syn-gas can be 100% reused for heating the pyrolysis reactor, no waste and no release also no pollution. So compared with the batch type waste tire pyrolysis plant, the fully automatic waste tire pyrolysis is better for environment.

Slagging in a compeleted sealed environment

Slagging in a compeleted sealed environment

On the whole, the fully automatic waste plastic pyrolysis plant has the features of small size, small floor area, simple operation, less operator and high efficiency etc. So choosing the fully automatic waste tire pyrolysis plant will be a good choose for you to start the waste tire recycling business. Welcome to leave us a message to get more information about the fully waste tire pyrolysis plant.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.